Since 1950, the best experts in galvanizing treatments

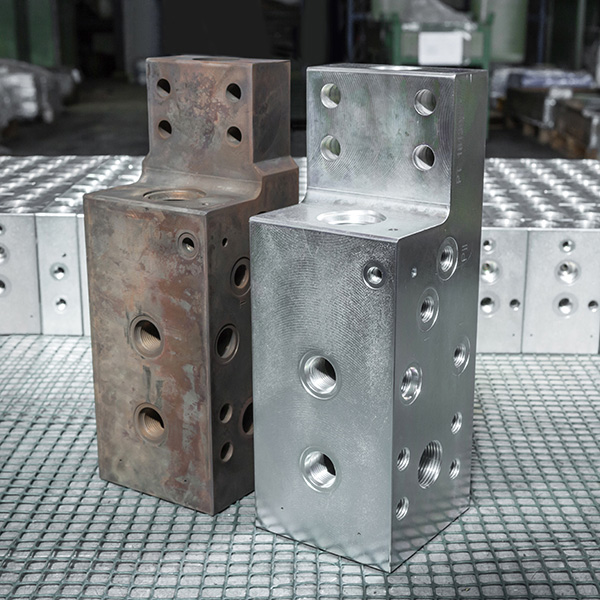

We carry out galvanizing treatments, standard electrolytic zinc plating, electrolytic zinc plating with high corrosion protection, Zinkel®, even on cast iron.

Since 1950, the best experts in galvanizing treatments

We carry out galvanizing treatments, standard electrolytic zinc plating, electrolytic zinc plating with high corrosion protection, Zinkel®, even on cast iron.

Since 1950, the best experts in galvanizing treatments

We carry out galvanizing treatments, standard electrolytic zinc plating, electrolytic zinc plating with high corrosion protection, Zinkel®, even on cast iron.

Our procedures

What allows us to guarantee the best quality and high standard at any stage is a great experience gained through the years and the avant-garde equipment available.

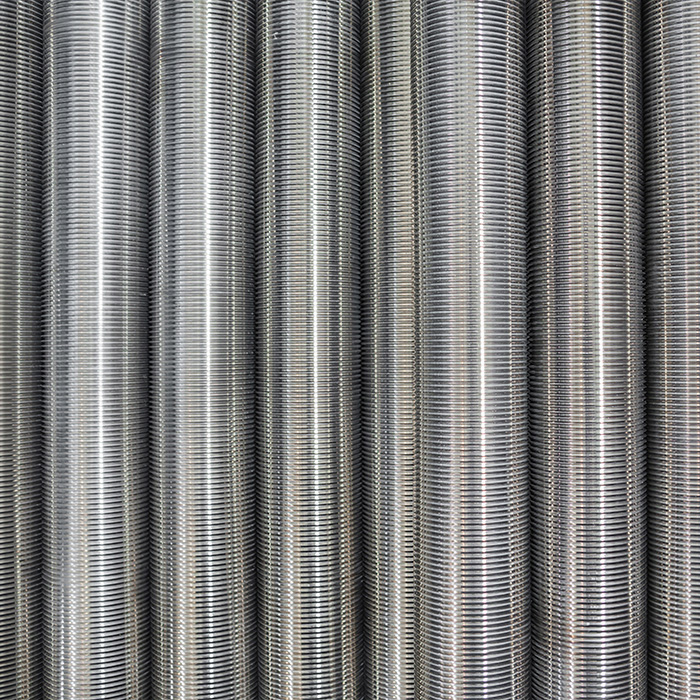

Standard electrolytic zinc plating

Zinc has an excellent protective power against iron. The protection is electrochemical in nature, since zinc is more electronegative than iron. In the atmospheric agents a galvanic pile is established in which the zinc behaves as an anode.

Galvanizing with high corrosion resistance

First step is a galvanizing process, with a thickness between 5 and 20 microns, which is subsequently protected by chromate with a high content of trivalent chromium, in order to give the deposit an iridescent color.

Innovative zinkel® (zinc-nickel) treatment

The Zinc Nickel is the most widespread process in the electrolytic deposition of zinc alloys. This treatment was conceived to meet the very high protection demand required by the automotive market.

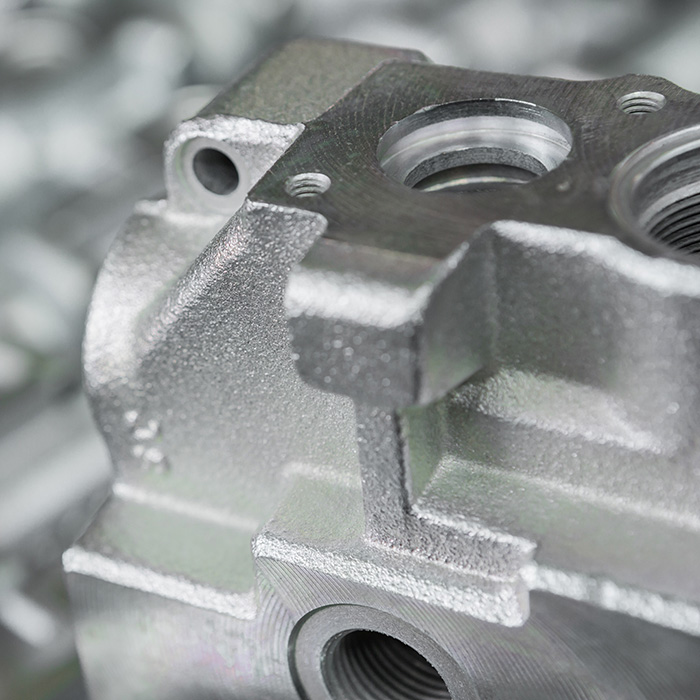

Galvanizing and zinkel® on cast iron

The cast iron (also called, until the nineteenth century, 'ferraccio' [bad iron] for the lower quality and the worst workability compared to mild steel) is a relatively high carbon alloy (2.11%

Zinc Nickel duplex frame

We installed a new system "duplex" frame with dedicated line to Zinc Nickel. Today, therefore, we can offer our customers not only the Zinkel® treatment with zinc-nickel acid, but also with alkaline zinc-nickel, so as to satisfy the automotive department.

Why metal treatment is so important

Protecting materials from the wear is our job. Why is it so important? Full functionality and integrity of each component means producing with high standards,

and recreate production excellence.

In an increasingly global and competitive world, which is changing ever faster, excellence is the only guarantee to keep up with the times and

ensure a future for a company.

GT Galvanotecnica since 1950.

Maximum support for every need.

Our Focus articles

Choosing GT Galvanotecnica means to rely on a qualified, competent and ever-available partner, which will respond to all of your requests..

Environment

Ecological treatments for our metal products.

Our company has been dedicating more and more resources and commitment to sustainable development for some time now.

Certifications

Also available:

- Certificate for the management system according to EN ISO 9001: 2008

- Certificate for the management system according to EN ISO 14001: 2004

Quality

High quality criteria for metal treatment. To GT Galvanotecnica, the products offered and the processing processes are very important and must meet a high quality criterion.

Other services

To meet the needs of each of our customers, we offer services such as:

- Dehydrogenation

- Brushing and rolling

- Packaging

- Transport

Tons of pieces treated every year

SqM plants

Referential partnerships

Employees

GT Galvanotecnica

via Pesenti, 86

46046 Medole (MN)